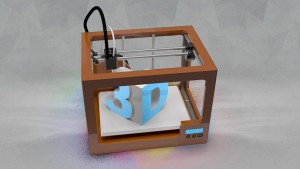

‘3D Printers’ which have become popular these days provide great savings on assembly costs because it can print already assembled products. 3D Printing is unlike of the common printers because on a 3D printer the object is printed by three dimension. It is a form of Additive Manufacturing (AM) technology where a three dimensional object is created by laying down successive layers of material.

‘3D Printers’ which have become popular these days provide great savings on assembly costs because it can print already assembled products. 3D Printing is unlike of the common printers because on a 3D printer the object is printed by three dimension. It is a form of Additive Manufacturing (AM) technology where a three dimensional object is created by laying down successive layers of material.

3D Printing also known as rapid prototyping—A mechanized method whereby 3D objects are quickly made on a reasonably sized machine connected to a computer containing blueprints for the object.

In terms of 3D advantages, 3D Printing offers multiple creations, from initial concept design to production of final products and all steps in between. 3D printer is mainly used in business enterprises and concepts which demand time-saving. These include medicine, architecture but also the entertainment industry such as game and film industry. Even artists use a 3D printer for their creations in a comparatively short time in a solid shape to print.

Today’s competitive environment makes choosing the right 3D printers more important than ever. This article focuses on 3D printers under Rs 100,000 and will help you to make the right choice.

On the same talking point, Vishal J.C., CEO, Grey Sim Ltd spoke to Electronic For You and mentioned,“3D printers started being used as geek tools and are now shaping up as user-friendly tools; even my eight-year-old daughter uses one for her school projects.”

Shiv Bhambri, CEO, RS Components & Controls Ltd, said, “3D printers are ideal for anyone who wishes to explore the fascinating world of 3D printing, build prototypes or even carry out small volume production.”

Under Rs 100,000, there are certain unique features such as fused deposition modelling (FDM). FDM is another method in which molten polymer is sprayed on a support layer and the model is built layer by layer. “The major advancement happening with respect to FDM is scaling down of the cost of 3D printers using this technology,” informs Prudhvi Reddy, co-founder, Think3D.

FDM printers can be divided into two groups—locked 3D printers and open 3D printers, informs Reddy.

Locked 3D printers: The whole printer is a locked system and the customer has to purchase the same company’s filaments

open 3D printers: A buyer can purchase 3D filaments from any available brand

Reddy also informed that both come with their own share of advantages and disadvantages. If a buyer prefers to go with a locked printer, he or she should check if filament supply and after-sale service is available.

With the same price range 3D printers available in the market are with respect to parameters such as build volume, price, number of extruders or underlying chips that make movements faster (speed of the printer).

It is important for a buyer to check the build volume, after-sales service, output quality and speed parameters before going for 3D printers under Rs 100,000. According to Vishal, speed is a misleading parameter to look for in FDM 3D printers under Rs 100,000, because almost all printers have similar speeds. He said, “We have to keep in mind that 3D printer is a rapid prototyping machine and not a substitute for mass production. It will boost conventional mass production as more ideas get physical manifestation, thereby increasing desktop manufacturing. Reliability is another important factor to consider.

For schools and universities, do-it-yourself (DIY) 3D printers are apt because of ease of use, learning, and of course, low price point.

Talking about the current price trends in 3D Printing, Raja Sekhar Upputuri, co-founder, Think3D commented, “In the past, printers sold for Rs 300,000 are now being sold for around Rs 100,000. In the next one year or so, these printers could even be available for less than Rs 50,000.”

This study clearly shows that in recent years 3D printers have become cheaper to produce. Nowadays several models are available for sale, as well as designs for products.

Today there are more and more companies that specialise in the printing of 3D models and supply services for business and individuals. Talking about the future development, “Nikhil Chowdary, technical head, Design & Prototyping Centre, ESCI – The Institution of Engineers (India) said, “Mass-automated 3D printing hubs with lowered costs of laser based 3D printing and multi-colour 3D printing using different technologies will be some other important additions in the coming years.”

There is also a lot of research on various kinds of materials that can be used to 3D print and on different scanning techniques.