Fujitsu today announced the start of a strategic collaboration with Phytocontrol Group (hereinafter Phytocontrol)(1), French leader in contaminant analysis for environmental and food safety. In August, the two companies signed a memorandum of understanding, and as part of this cooperation Fujitsu and Phytocontrol will develop chromatography(2) analysis services supported by artificial intelligence.

These services aim to contribute to ensuring food safety by speeding up and improving the accuracy of contaminant analysis in the food industry and to contribute to the digital transformation (DX) of various analytical business processes by expanding services based on this analysis technology to other industries including healthcare and cosmetics on a global level.

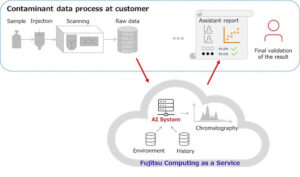

Together, Fujitsu and Phytocontrol will offer end to end AI chromatography analysis technology via “Fujitsu Computing as a Service” (CaaS) – Fujitsu’s service portfolio that makes advanced computing technologies available to users via the cloud – to provide chromatography analysis services to food companies, distributors, and regulators over the world. Fujitsu and Phytocontrol aim to start provision of the new service during fiscal 2023.

This collaboration with Phytocontrol is an element in Fujitsu’s ongoing commitment to providing optimal IT environments and solutions that meet the diverse needs of customers under Fujitsu Uvance, its global business brand to realize a sustainable world.

Global food crisis: growing need for food security

The ever-worsening global food crisis remains an ongoing issue, as approximately 400,000 people worldwide die each year from the consumption of contaminated food(3).

To this end, food safety and ensuring that contaminants and pollutants do not enter the food production and supply chain represents an important task. However, the fast and accurate analysis of contaminants in food gained in importance in recent years due to increasing numbers of a variety of contaminants in food and the need to analyze a growing number of different food samples.

To address this issue, Fujitsu and Phytocontrol in 2020 developed a system integrating Fujitsu’s AI technology that automates the process of contaminants analyses in food and water. The AI system is not only able to accelerate analysis time from the extraction of raw data per sample to the verification of results by a factor of 5, but can also reduce human errors, improving operational efficiency and accuracy significantly(4).

Based on these efforts, Fujitsu and Phytocontrol started further cooperation to offer their AI based analysis system as a service via Fujitsu’s CaaS to provide advanced and easy-to-use technology to a wide range of players in the food industry.

Outline of Collaboration

1. Global provision of CaaS component analysis services for food contamination

Fujitsu’s CaaS encompasses advanced computing resources like Fujitsu’s quantum inspired Digital Annealer technology, the computing technology of supercomputer Fugaku, and software applications that allow a wide range of users to solve problems with AI and machine learning via the cloud. Fujitsu CaaS will be available to the Japanese market in October 2022 and expanded to the global market during fiscal 2023.

As part of their collaboration, Fujitsu and Phytocontrol will build a food contaminant component analysis service that they aim to provide to a wide variety of stakeholders, including food companies, distributors, and regulatory authorities via Fujitsu’s CaaS. The two companies aim to support fast and accurate analysis of contaminant components in the food industry and to contribute to ensuring food safety.

2. Expansion into other industries including healthcare and cosmetics

The two companies plan to apply services based on AI chromatography analysis technology to a wide range of industries besides the food industry, including healthcare and cosmetics and plan to offer services to the European and global market. In this way, Fujitsu and Phytocontrol aim to not only ensure safety in the food industry, but also to contribute to solving issues in various industries by promoting DX.

Toshiaki Ariyama, SVP, Head of Uvance Core Technology Unit, Fujitsu Limited, comments:

Through this strategic collaboration, we look forward to providing a wide range of cloud services via “CaaS” based on Phytocontrol and Fujitsu’s accumulated technologies and know-how. Together, we aim to deliver a service that ensures the safety of food and water, supports people’s lives, and contributes to the realization of a sustainable society.

Mikael Bresson, Founder and CEO of Phytocontrol Group comments:

We are successfully working with Fujitsu for more than 2 years now to digitalize our production processes. We believe that the “Fujitsu Computing as a Service” (CaaS) is a very good opportunity to speed-up and scale-up our collaboration to grow our business with fast and reliable chromatography analysis using artificial intelligence around the world.

(1) Phytocontrol Group :

Headquarters: Nimes, Frances; Founder and CEO: Mikael Bresson.

Phytocontrol Group purpose is to guarantee the safety of food and the environment by providing innovative technical solutions and complete support for laboratory analyses, regulatory monitoring and training, quality audits and digital traceability. Its teams of specialists are structured around 3 markets AgriFood (food processing), Waters (hydrology) and BioPharma (Good Laboratory Practice studies) to meet the health safety needs of all types of clients. Phytocontrol thus strives to guarantee local support and a quality service that sets itself apart in terms of responsiveness and reliability.

Find out more: www.phytocontrol.com

(2) Chromatography :

A general term for the separation and analysis of the components of compounds in substances. Since the elution time is different for each component, each component is separated and detected.

(3) Approximately 400,000 people worldwide die each year from the consumption of contaminated food :

(Source) World Health Organization (WHO) “Estimating the burden of foodborne diseases”

(4) Fujitsu / Phytocontrol use case