Hitachi, Ltd. (TSE: 6501) has announced that the company will support the manufacturing of ventilators essential in the pandemic situation by providing a free cloud service for 3D procedure manuals using Hitachi’s assembly navigation system.

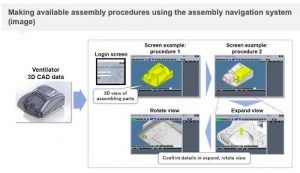

Hitachi’s assembly navigation system converts 3D CAD design data of finished products into 3D procedure manuals.A healthcare company Medtronic (headquartered in Ireland) has made the ventilator design specification(3D CAD data) available free of charge.These design specifications have been incorporated and this system will publish the assembly processes after each process is automatically made into a procedure. After an year this will be available on a cloud service (SaaS) and can be easily navigated in a web browser.

Hitachi’s assembly navigation system was commercialized in November 2017.The production drawings are based on 3D CAD data.The workers follow that plan as they do the assembly, but having to interpret specialized production drawings while doing the assembly puts a burden on the production site.

This system incorporates design and structural information from the 3D CAD data of the finished product, analyzes the sequences and actions through an original algorithm, and automatically generates a 3D procedure manual with a suitable assembly order. Each operation is shown on one screen in a simple way, so that the workers can easily interpret the assembly order from a production drawing and proceed with the assembly following the different procedures displayed on the screen. The designs and structures can be understood in detail by rotating, enlarging, and shrinking them.

The company has prioritized the health and safety of customers, partners, employees working globally as well as their families, and all other stakeholders and is ensuring the prevention of the disease’s spread.

Since 1969,Hitachi’s Omika Works (Hitachi, Ibaraki), the developer and provider of the assembly navigation system, has provided information control systems for railways, electric power, water and sewage systems, and other important social infrastructure. It has consistently engaged itself in providing everything from design to manufacturing of hardware and software as well as the operation and maintenance of overall systems.It has been recognized as one member of the “Lighthouse” global advanced factories at the World Economic Forum.