“India poised to grow and become the world’s largest aluminium die casting base”

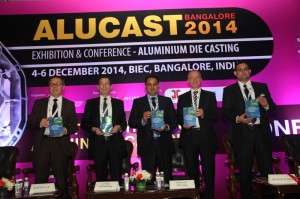

India’s biggest exhibition for the Aluminium Die Casting Industry,  ALUCAST 2014, flagged off today at Bengaluru International Exhibition Centre. The inauguration ceremony started with a Welcome speech by Mr. Prasan Firodia, President, Alucast & Managing Director, Force Motors, India, and Address by Mr. Rolf Keller, Member Management Board, NuernbergMesse, Germany. The Exhibition & Conference is organised by The Aluminium Casters’ Association of India and the Event has been produced by NuernbergMesse India.

ALUCAST 2014, flagged off today at Bengaluru International Exhibition Centre. The inauguration ceremony started with a Welcome speech by Mr. Prasan Firodia, President, Alucast & Managing Director, Force Motors, India, and Address by Mr. Rolf Keller, Member Management Board, NuernbergMesse, Germany. The Exhibition & Conference is organised by The Aluminium Casters’ Association of India and the Event has been produced by NuernbergMesse India.

The biennial event has emerged as a perfect convergence platform for numerous stakeholders across the Aluminium Die Casting Industry and attracts Exhibitors & Visitors from across the globe. The exhibitor spectrum of ALUCAST 2014 included products and services from Aluminium Die Casting, Aluminium Recycling, Automation of Casting Process, Melting Practices and Metal Treatment, Post Casting Operations, Heat Treatment Specialists Instrumentation and Control, Software Systems Integration/Rapid Prototyping, Die Casting Machinery Manufactures, Die Manufacturers, and Machine Tools.

Speaking on the occasion, Mr. Prasan Firodia, President, Aluminium Casters’ Association of India said, “India has emerged as a significant player in the global automotive supply chain. This industry accounts for 7% of India’s GDP. With continued development in the infrastructure and entry of newer FDI’s, auto component industry will be further boosted. This will have a positive impact on the die-casting industry as an estimated 60% of the die castings produced in India are used in the auto Industry. Added to this we have an advantage of educated labour at competitive costs and economies of operations. This should help the industry grow and become the world’s largest aluminium die casting base. There is an expectation that the new government will provide the country with an environment that will revitalize manufacturing especially the automobile sector. One can already see encouraging signs with the Union budget supporting infrastructure and increased private investments. There is also the new foreign Trade policy for 2014-2019 which is designed with a long term strategy to boost the manufacturing sector and to bring it in line with the “Make in India” goal.”

The global auto Industry is moving towards improving fuel efficiency by reducing the weight of vehicle. Replacement of heavier parts made from cast iron and steel by lighter aluminium parts is the future. These aluminium parts are now further being redesigned to achieve lower weights. The Theme of this year’s Conference “Light weighting of Aluminium Castings” is therefore very appropriate and timely. Experts of international repute presented and will present papers during the Conference sharing their knowledge and experience. Topics like – Light weighting by product re-engineering and Change of production process, Die casting Technology for Structural Parts, and Advantage of using Vacuum Technology for light weighting PDC Parts are a few presentations that the attendees looked forward to.

Speaking on the occasion, Ms. Sonia Prashar, Managing Director, NuernbergMesse India said, “ALUCAST 2014 perfectly fits the existing portfolio of NürnbergMesse Group’s long-established die casting industry events in other regions. With EUROGUSS in Nuremberg, the leading international trade fair for die casting in Europe, and China International Die casting in Shanghai. At this year’s edition of ALUCAST, we have a record number of over 100 exhibitors, approx. 2500 visitors & participation from more than 10 countries – a marked growth from the event in 2012. These impressive numbers correspond to the growing importance of the die casting industry in India. It has seen enormous growth over the last years, especially in its role as a supplier of the booming automotive sector. Global automotive companies increasingly perceive India as a hub for sourcing and manufacturing, with the domestic markets offering high potentials. Many manufacturers seek to improve fuel efficiency to reduce carbon emissions. Lightweight construction has consequently become a key issue and aluminium is among the most popular materials. At ALUCAST, we intend to offer a business platform which gives participants a perfect platform to showcase the latest products and services on offer and network with the global audience.”

The Inaugural ceremony was followed by Felicitation of Mr. Pran Sadhu, Trustee & Former President, Alucast &former Vice President, Sunbeam Auto and Release of Technical Volume, Alucast Journal, Alucast Directory, Foundry Awards.