1 min read

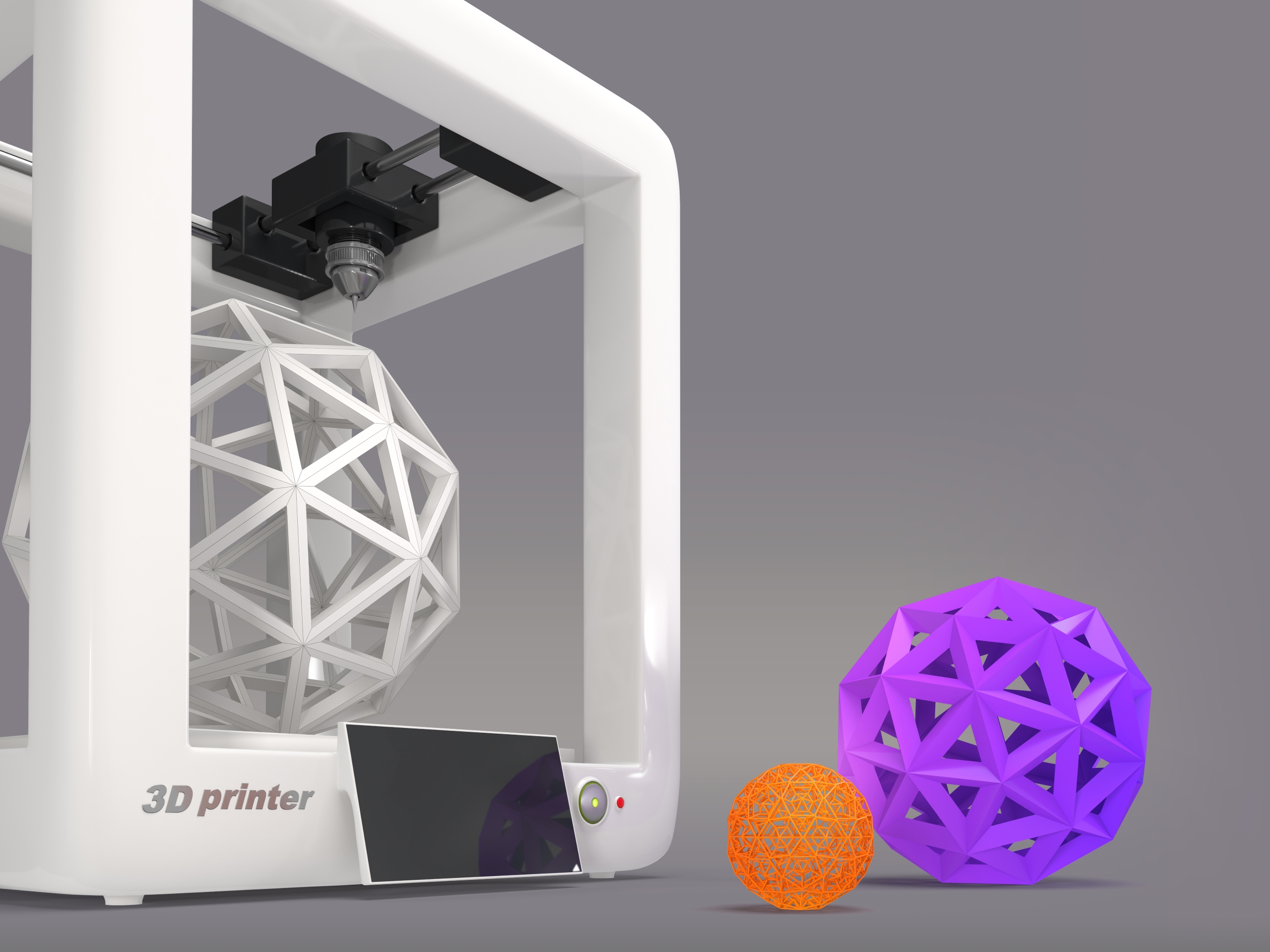

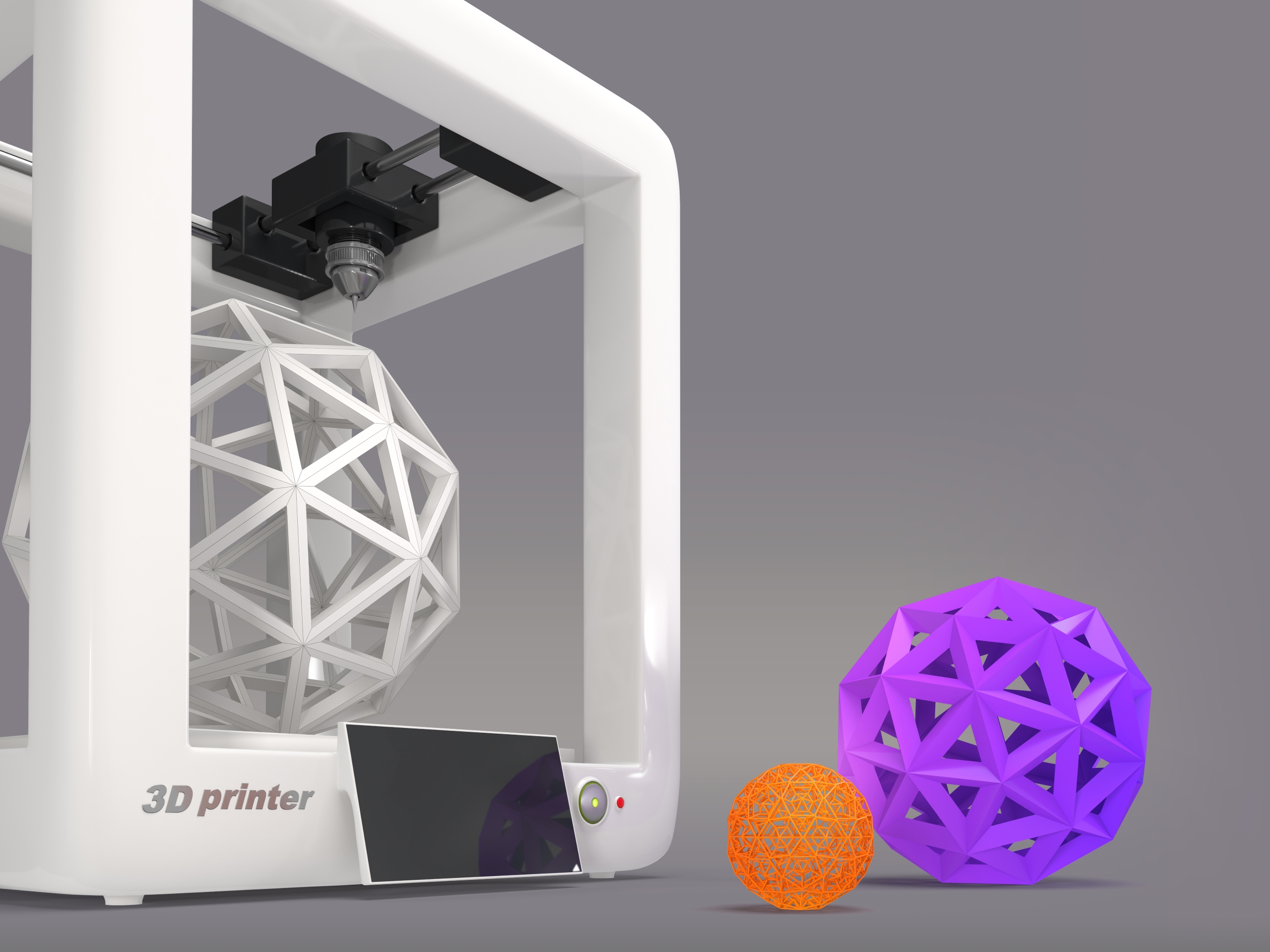

Nanodiamonds boost 3D printed polymer performance

Copyright 2023, IT Voice Media Pvt. Ltd.

All Rights Reserved

Finnish nanodiamond manufacturer Carbodeon and Dutch 3D printing specialist Tiamet 3D have announced the first nanodiamond-enhanced filaments for 3D printing.

Finnish nanodiamond manufacturer Carbodeon and Dutch 3D printing specialist Tiamet 3D have announced the first nanodiamond-enhanced filaments for 3D printing.